Introduction

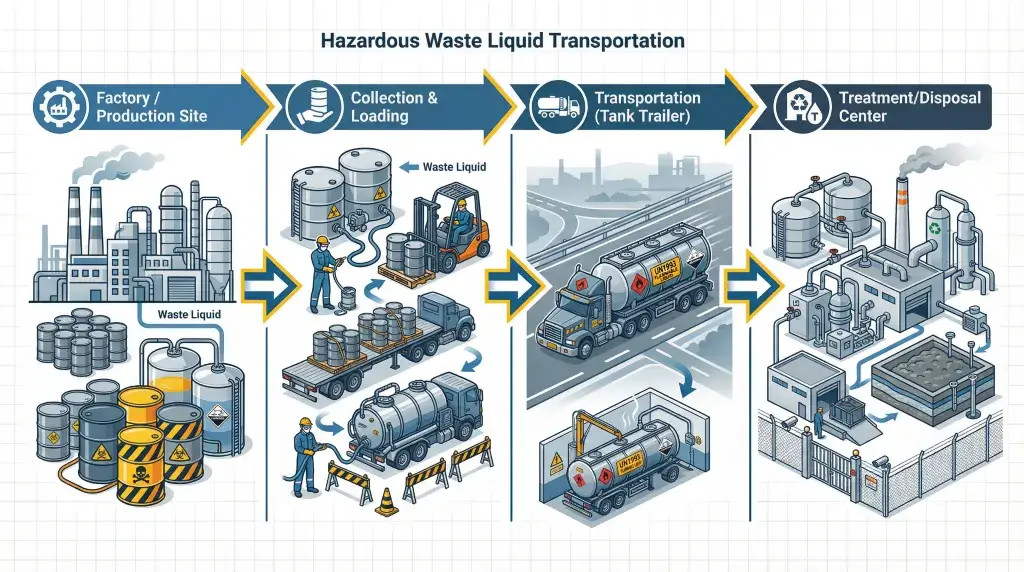

The transportation of hazardous and industrial waste liquids is one of the most regulated and risk-sensitive segments in the logistics industry. Unlike fuel or general chemical transport, hazardous waste liquid transport requires specialized tank trailers designed to prevent leaks, resist corrosion, and comply with strict environmental regulations.

For environmental service providers, industrial waste treatment companies, and hazardous waste management operators, choosing the right tank trailer is not just a purchasing decision—it is a compliance and risk management strategy.

This article explains why tank trailers are essential for hazardous waste liquid transport, who uses them, and how to choose the right solution for this highly specialized application.

What Is Hazardous Waste Liquid Transport?

Hazardous waste liquid transport refers to the movement of liquid waste materials that pose environmental or health risks if improperly handled. These liquids often originate from industrial processes and must be transported to licensed treatment or disposal facilities.

Common hazardous waste liquids include:

-

Acidic and alkaline waste liquids

-

Electroplating wastewater

-

Chemical byproducts and residues

-

Industrial sludge in liquid form

Due to the nature of these materials, regulations typically mandate the use of certified tank trailers rather than general-purpose transport equipment.

Why Tank Trailers Are Essential for Hazardous Waste Liquids

Standard tank trailers designed for fuel or food-grade liquids are not suitable for hazardous waste transport. Specialized tank trailers are required for the following reasons:

1. Leak Prevention and Environmental Protection

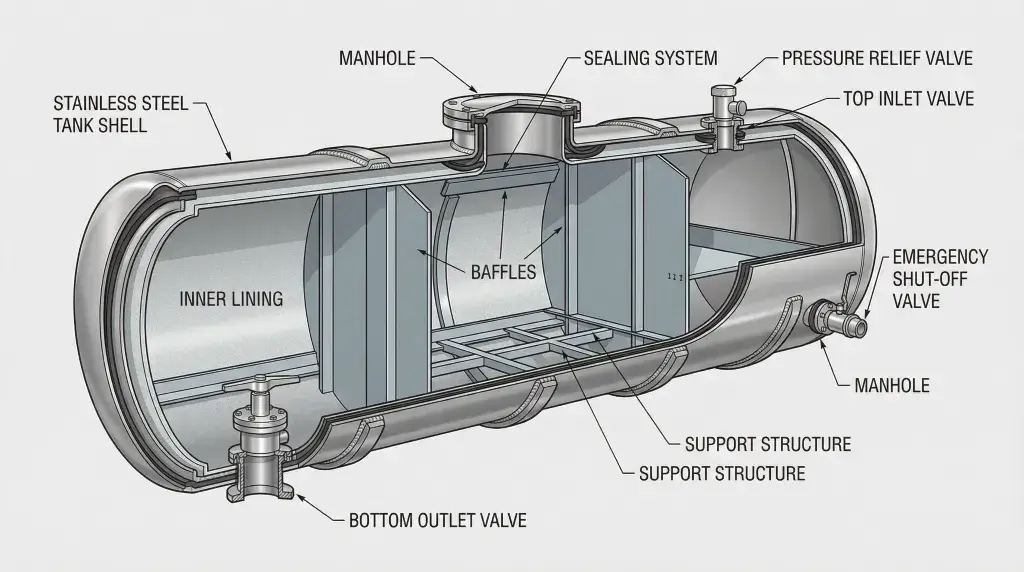

Even minor leaks can result in severe environmental damage, regulatory penalties, and operational shutdowns. Hazardous waste tank trailers are built with reinforced structures, secure valves, and multi-layer sealing systems to minimize risk.

2. Corrosion Resistance

Many waste liquids are highly corrosive. Tank trailers for hazardous waste often use:

-

Stainless steel tanks

-

Protective internal linings (e.g., PTFE or epoxy coatings)

This ensures long-term durability and safety.

3. Regulatory Compliance

Environmental and transportation authorities require certified equipment for hazardous waste movement. Compliance is not optional—it is a prerequisite for operation.

Who Uses Hazardous Waste Tank Trailers?

1. Hazardous Waste Management Companies

Typical Role: Collection and transport of liquid hazardous waste from factories to treatment facilities

Fleet Size: Usually 5–30 trailers

Key Concern: Safety, compliance, and reliability

These companies rely on tank trailers that meet hazardous material transport standards to maintain operating licenses.

2. Environmental Engineering & Industrial Cleaning Companies

Typical Role: On-site waste liquid removal and transportation

Key Challenge: Transporting mixed or variable waste liquids

Trailer Requirements: Flexible tank configurations, secure discharge systems, and easy cleaning

3. Industrial Manufacturers with In-House Waste Transport

Typical Industries: Chemical processing, electroplating, metal finishing

Key Challenge: High-frequency waste liquid transport under strict compliance rules

Decision Logic: Reliability and documentation support over price

Key Tank Trailer Specifications for Hazardous Waste Transport

When selecting a tank trailer for hazardous waste liquids, buyers should focus on the following specifications:

Tank Material

-

Stainless steel for high corrosion resistance

-

Internal coatings for aggressive chemical waste

Safety Systems

-

Emergency shut-off valves

-

Pressure relief valves

-

Anti-leak discharge systems

Structural Design

-

Reinforced tank shell

-

Smooth internal surfaces to prevent residue buildup

Certification & Compliance

-

DOT / ADR / UN certifications

-

Documentation for environmental audits

How Buyers Make Decisions in This Niche Market

Unlike general logistics customers, hazardous waste transport operators follow a risk-first decision model:

-

Regulatory compliance

-

Safety record and design

-

Tank material and corrosion resistance

-

After-sales support and technical documentation

-

Price

This makes hazardous waste tank trailers a high-barrier, high-retention market with strong long-term customer relationships.

Benefits of Specialized Tank Trailers for Hazardous Waste

-

Reduced Environmental Risk: Designed to prevent leaks and spills

-

Regulatory Confidence: Supports audits and inspections

-

Lower Long-Term Costs: Durable materials reduce replacement frequency

-

Operational Stability: Minimizes downtime caused by equipment failure

Conclusion

Hazardous and industrial waste liquid transport is not a mass-market application—it is a specialized, regulation-driven industry where the right tank trailer makes a measurable difference. Environmental service providers and waste management companies need equipment that prioritizes safety, durability, and compliance above all else.

By investing in tank trailers specifically engineered for hazardous waste liquids, businesses can protect their operations, maintain regulatory approval, and build long-term trust with industrial clients.

For regulatory details, see our hazardous waste tank trailer compliance checklist.