Introduction

For companies involved in hazardous waste liquid transport, compliance is not just a legal requirement, it is a business survival issue. A single non-compliant tank trailer can lead to heavy fines, operational shutdowns, and long-term reputational damage.

This compliance checklist is designed for hazardous waste transport operators and environmental service companies who need to ensure their tank trailers meet DOT, ADR, and UN regulations before purchase or deployment.

If you are evaluating a tank trailer supplier, this checklist can also be used as a pre-purchase verification tool.

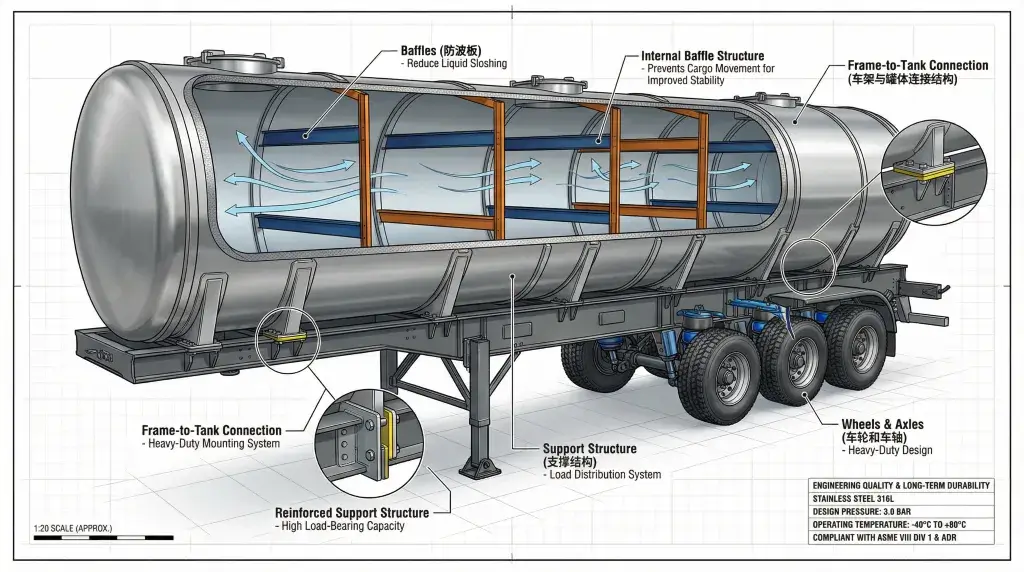

1. Tank Design Compliance

The foundation of regulatory compliance starts with tank design.

Key requirements include:

-

Proper shell thickness according to hazardous material classification

-

Reinforced heads and weld joints

-

Internal baffles to control liquid surge

-

Design pressure suitable for hazardous liquids

A non-compliant tank structure may pass visual inspection but fail under regulatory audit.

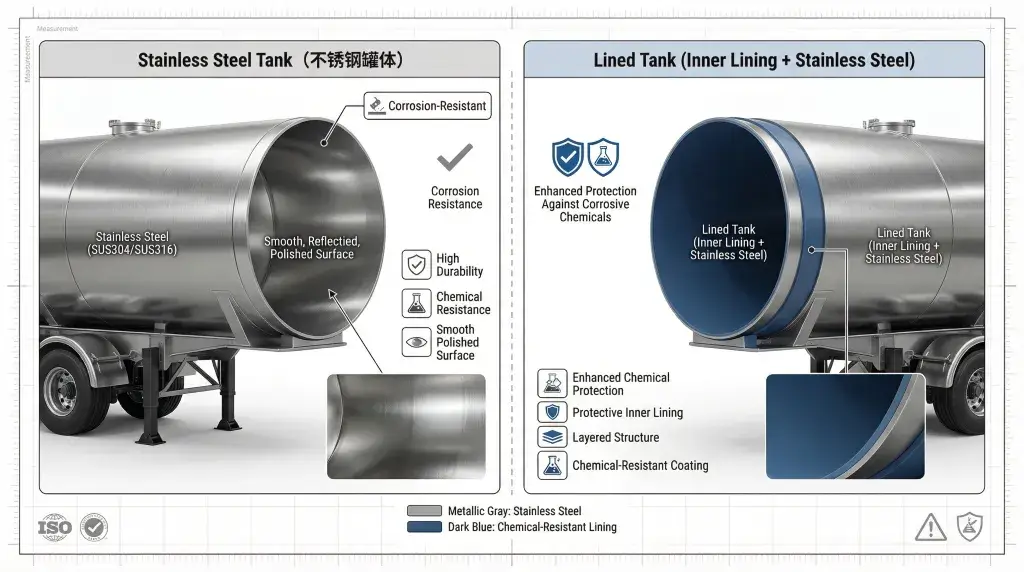

2. Material Certification and Chemical Compatibility

Hazardous waste liquids are often corrosive, reactive, or unstable.

Compliance requires:

-

Certified stainless steel or approved lined tanks

-

Material test reports (MTR)

-

Chemical compatibility documentation

Regulators may request proof that tank materials are suitable for the specific waste class being transported.

3. Valve, Sealing, and Leakage Prevention Requirements

Leak prevention is a core focus of DOT and ADR inspections.

Checklist items include:

-

Certified discharge valves

-

Multi-layer sealing systems

-

Emergency shut-off devices

-

Secondary containment where required

Even minor leakage can result in immediate operational suspension.

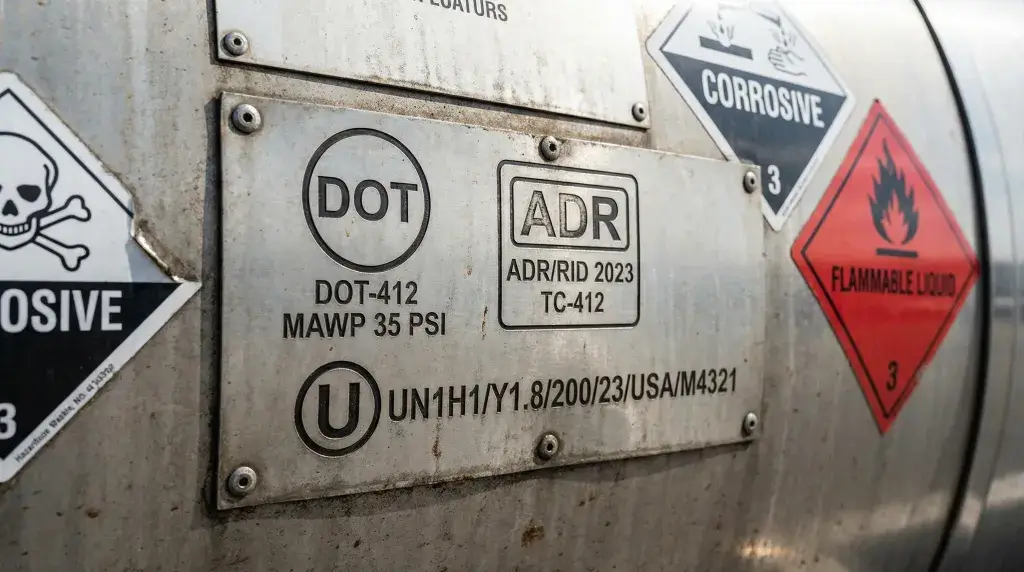

4. Identification, Marking, and Documentation

Every compliant hazardous waste tank trailer must have:

-

Permanent identification plates

-

Clear hazard markings

-

UN / DOT specification labels

-

Serial numbers traceable to manufacturing records

Missing or incorrect markings are one of the most common reasons for inspection failure.

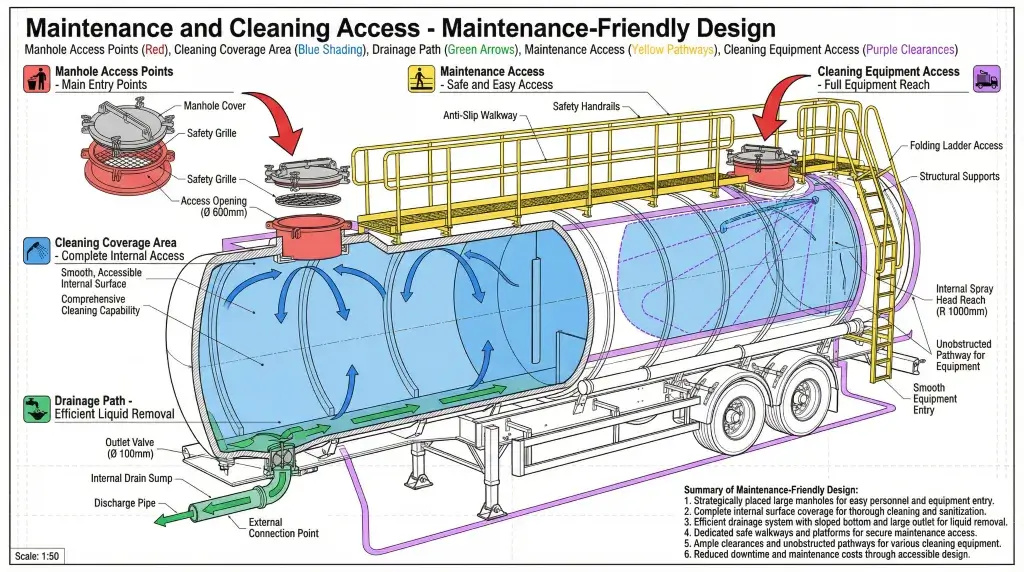

5. Cleaning, Inspection, and Maintenance Accessibility

Regulations require regular inspection and cleaning, especially when transporting multiple waste types.

Compliance-friendly design includes:

-

Accessible manways

-

Drainage systems that minimize residue

-

Compatibility with CIP cleaning systems

Poor accessibility increases contamination risk and inspection downtime.

6. Supplier Documentation and Technical Support

Compliance does not end with the trailer itself.

A qualified supplier should provide:

-

Complete certification packages

-

Technical drawings and specifications

-

Ongoing compliance support

Without proper documentation, even a well-built trailer can become unusable.

Final Compliance Checklist Summary

Before purchasing or operating a hazardous waste tank trailer, confirm that:

-

The tank structure meets DOT / ADR design requirements

-

Materials are certified and chemically compatible

-

Valves and seals prevent leakage

-

Identification and markings are correct and permanent

-

Cleaning and inspection access is compliant

-

Full documentation is available

Conclusion

Hazardous waste tank trailer compliance is a system, not a single feature. Companies that treat compliance as a checklist rather than an afterthought significantly reduce operational risk and regulatory exposure.

For hazardous waste transport operators, selecting a fully compliant tank trailer is not only about avoiding penalties, but about building a safe, reliable, and sustainable operation.