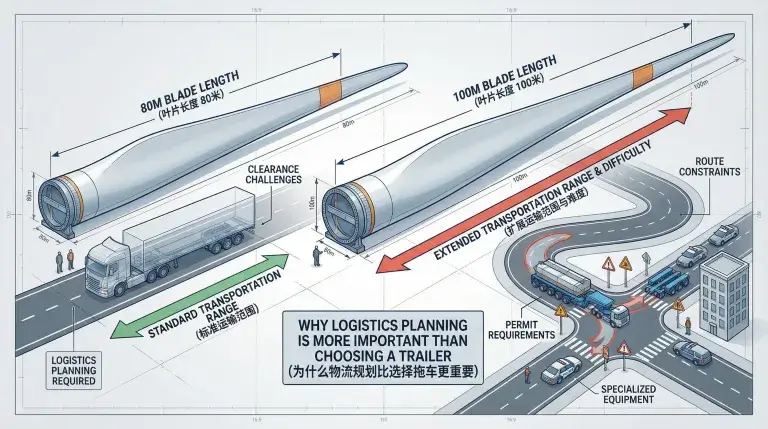

Transporting wind turbine blades has never been a simple task. As turbine blades grow longer—often exceeding 80 meters—the logistical challenges increase dramatically. While choosing the right extendable wind blade trailer is crucial, modern wind energy projects require a deeper understanding of transportation strategies, advanced trailer technologies, and regulatory considerations. This article explores these aspects in depth, providing actionable insights for logistics managers, project planners, and equipment engineers.

Why Wind Blade Logistics Is More Critical Than Ever

Wind turbine blades have evolved dramatically in the last decade. Larger rotor diameters and longer blades offer higher energy yields, but they also create significant challenges for transportation:

-

Increased Blade Lengths: Blades exceeding 80–100 meters require trailers with advanced extendable systems, multi-axle steering, and optimized load distribution.

-

Complex Routes: Projects often involve remote or mountainous locations, narrow roads, or urban environments where standard trailers cannot maneuver safely.

-

Project Timelines: Delays in blade transport can stall entire wind farm installations, impacting costs and project deadlines.

The combination of size, weight, and route complexity makes logistics planning as important as trailer selection.

Beyond Choosing a Trailer: Comprehensive Transport Solutions

While selecting an extendable trailer is the first step, the complete transportation solution involves multiple technologies and operational strategies.

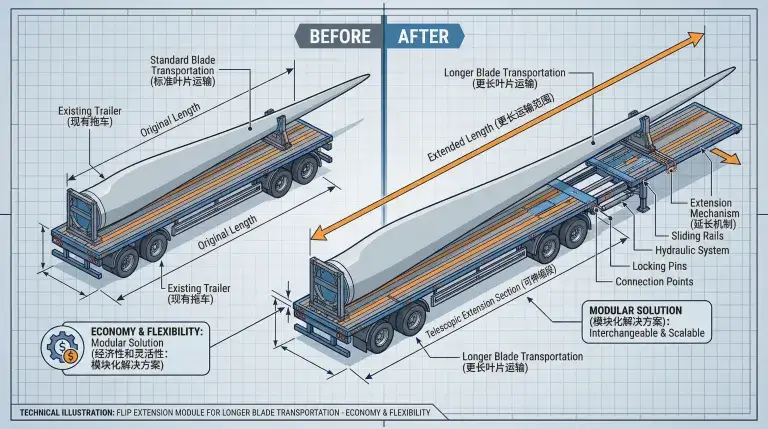

Extendable and Auxiliary Trailer Components

Modern extendable trailers are not all created equal. Many manufacturers now offer modular extensions or “flip extension” systems, which allow trailers to adapt to longer blades without purchasing entirely new units. These systems provide flexibility for projects with variable blade sizes while maintaining stability and compliance with local regulations.

Key Benefits:

-

Reduce capital expenditure on multiple trailer units.

-

Adapt to new blade lengths as turbine designs evolve.

-

Simplify cross-border logistics by adjusting trailer length to meet regional road regulations.

Example: BladeMate Flip Extension enables longer blades to be transported safely using existing trailer platforms. (NA Wind Power)

Steering and Suspension Innovations

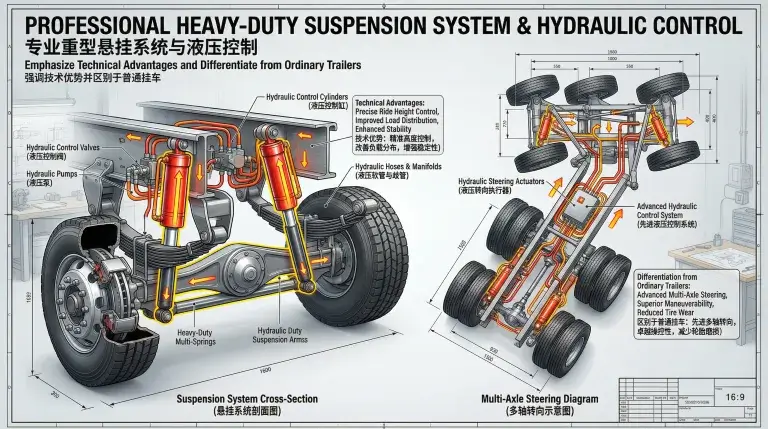

Blade transport requires precise control over trailer dynamics. Unlike standard road trailers, wind blade trailers incorporate:

-

Hydraulic multi-axle steering systems: Allow tight turns and reduce stress on long blades.

-

Air or hydraulic suspension: Minimizes vibration and maintains consistent blade alignment over uneven terrain.

-

Dynamic weight distribution: Critical for blades exceeding 50 meters, especially when navigating bridges or sloped roads.

These features not only protect the structural integrity of the blades but also ensure compliance with transportation safety standards.

Safety Compliance and Certification

Compliance with international transport regulations is non-negotiable:

-

DOT and ADR regulations govern trailer dimensions, axle loads, and road safety in North America and Europe.

-

Height and turning limitations must be addressed when planning routes in urban or mountainous areas.

-

Documentation and inspection records are required for cross-border logistics.

Selecting trailers with built-in compliance features and modular certification options reduces operational risk.

Handling Complex Terrains and Special Operations

Not all wind blade routes are straightforward highways. Many projects involve:

-

Mountain passes where trailer articulation must allow for sharp turns.

-

Narrow corridors requiring multi-axle steering with synchronized hydraulic controls.

-

Rotational maneuvers to navigate obstacles such as bridges, tunnels, or power lines.

Some logistics teams employ specialized transport jigs or temporary pivot systems to safely rotate and reposition blades during these challenging maneuvers. (Shiyun Vehicle)

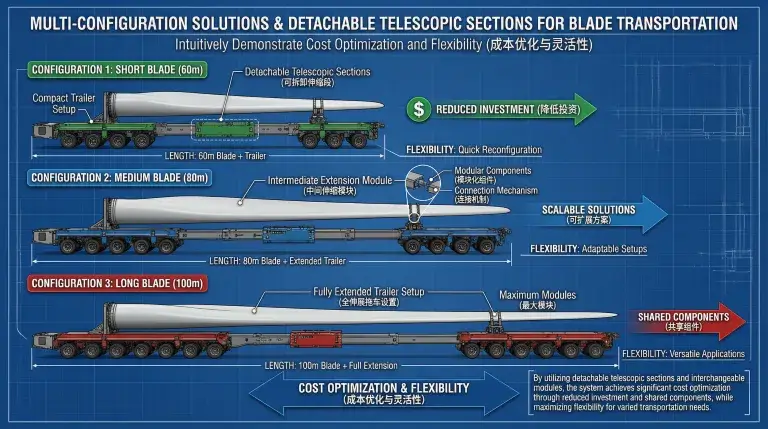

Reducing Operational Costs Through Modular and Flexible Solutions

Operational efficiency is just as critical as safety. Modern wind blade trailers incorporate modular designs that allow:

-

Interchangeable components: Extendable sections or steering modules can be swapped to suit different blade sizes.

-

Reduced fleet size: One flexible trailer can handle multiple blade lengths, reducing capital expenditure.

-

Cross-border adaptability: Modular extensions simplify regulatory compliance and avoid costly route detours.

By optimizing trailer configurations for project-specific requirements, companies can significantly reduce transportation costs per blade, while maintaining safety and reliability.

Industry Challenges and Emerging Trends

Several trends are shaping the future of wind blade transport:

-

Even Longer Blades: As blade lengths continue to exceed 100 meters, trailers must be engineered for higher extension ratios while maintaining torsional rigidity.

-

Remote Monitoring and Smart Trailer Systems: Telemetry-enabled trailers can monitor blade stress, alignment, and transport conditions in real time, enabling proactive risk management.

-

Automation in Logistics Planning: AI-based route optimization is increasingly used to simulate transport scenarios, helping planners avoid delays and reduce risk.

-

Sustainability Considerations: Modular and reusable trailer designs contribute to lower carbon emissions and resource efficiency across multiple projects.

These innovations are not just futuristic—they are essential for meeting the demands of large-scale wind energy deployment.

Conclusion: Partnering for Global Wind Projects

Choosing the right extendable trailer is just the beginning. Successful wind blade transportation requires a holistic approach: integrating advanced trailer technology, steering and suspension innovations, route planning, compliance, and cost optimization.

By combining modular trailer designs, multi-axle steering, and digital monitoring systems, wind energy companies can:

-

Safely transport increasingly large blades

-

Reduce project delays and costs

-

Prepare for the next generation of turbine designs

In an industry where blade lengths are ever-increasing, logistics innovation is as critical as turbine innovation. Partnering with experienced trailer manufacturers and logistics specialists ensures that wind projects stay on schedule, safely and efficiently.