Introduction

Hazardous waste tank trailers operate under extreme conditions: corrosive liquids, regulatory pressure, and high safety risks. While many operators focus on purchase price and basic specifications, real-world failures usually come from hidden design and maintenance weaknesses.

This article highlights the most common failure types in hazardous waste tank trailers — based on real operational scenarios — and explains how to avoid them through proper design and supplier selection.

Primary Keywords:

hazardous waste tank trailer failures, chemical tanker leakage issues, industrial waste transport risks.

1. Corrosion-Induced Tank Damage

Corrosion is the number one silent killer of hazardous waste tank trailers.

Common causes:

-

Incompatible tank materials

-

Poor internal lining quality

-

Insufficient corrosion monitoring

Results:

-

Tank wall thinning

-

Structural weakness

-

Sudden leakage under pressure

Many failures occur internally and invisibly, only discovered after serious damage.

2. Valve and Sealing System Failures

Valve failure is the most common direct cause of hazardous liquid leakage.

Typical problems:

-

Low-quality discharge valves

-

Degraded sealing materials

-

Lack of emergency shut-off systems

Even a small sealing failure can lead to:

-

Environmental contamination

-

Regulatory penalties

-

Immediate suspension of operations

3. Structural Fatigue and Frame Cracking

Hazardous waste liquids vary in density and flow behavior. Without proper structural design, tank trailers experience uneven stress distribution.

Failure symptoms:

-

Frame cracks

-

Weld joint fatigue

-

Tank mounting deformation

These issues often appear after long-term operation and are difficult to repair economically.

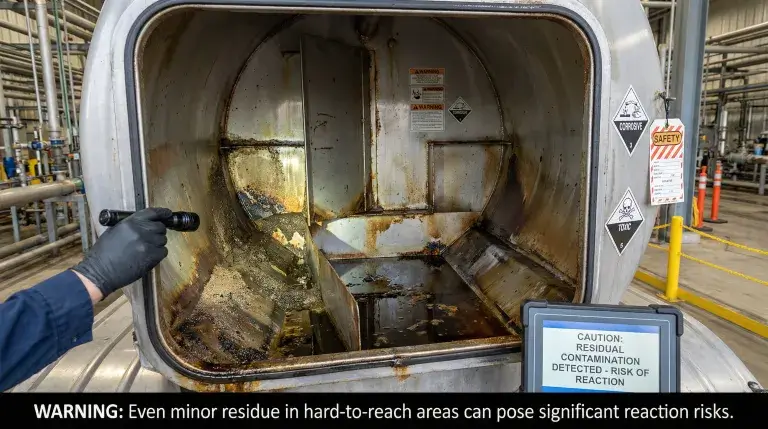

4. Inadequate Cleaning and Residue Buildup

Poor cleaning access leads to chemical residue accumulation, increasing the risk of:

-

Cross-contamination

-

Unexpected chemical reactions

-

Inspection failures

This is especially dangerous for operators transporting multiple waste types.

5. Documentation and Compliance Failures

Surprisingly, many operational shutdowns are not caused by mechanical issues — but by missing or incomplete documentation.

Common problems:

-

Missing certification plates

-

Incomplete inspection records

-

Non-traceable serial numbers

Even a perfectly functioning trailer can be legally unusable without proper documentation.

How to Avoid These Failures

The most effective prevention strategies include:

-

Selecting corrosion-resistant materials

-

Using certified valve and sealing systems

-

Reinforcing structural design for liquid dynamics

-

Designing for easy cleaning and inspection

-

Working with suppliers who provide full compliance documentation

Conclusion

Most hazardous waste tank trailer failures are not random — they are predictable and preventable. Operators who understand these risks early can avoid costly downtime, regulatory penalties, and long-term safety hazards.

In hazardous waste transport, reliability is not defined by how the trailer looks on delivery day, but by how it performs after years of exposure to extreme chemical and regulatory environments.